Phases can be predicted and parametric studies can be performed to optimize the alloy dependent heat treatment conditions during austenitization, quenching and ausferritization.

#Magmasoft system requirements software#

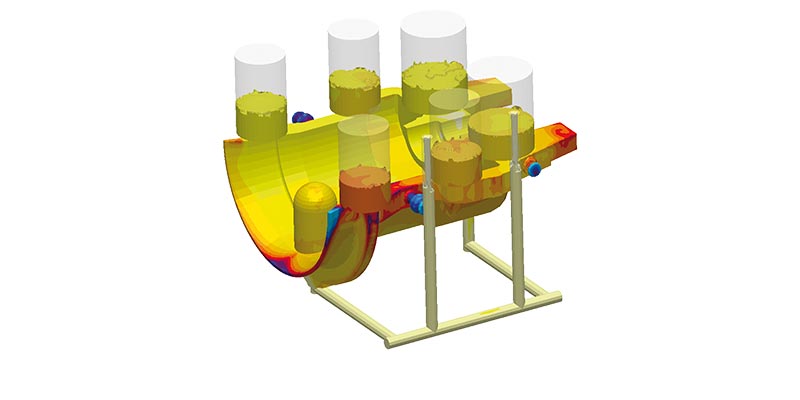

As the property requirements for cast iron as a material in design strongly increase, new alloys and materials such as ADI might become more attractive, where latest software developments allow the modeling of the required heat treatment. Cracks in castings can be assessed, as well as the reduction of casting stresses during heat treatment. State-of-the-art tools allow the prediction of residual stresses and iron casting distortion quantitatively. Casting quality issues related to thermally driven stresses in castings are also gaining increasing attention. This allows the prediction of local structures, phases and ultimately the local mechanical properties of cast irons, to asses casting quality in the foundry but also to make use of this quantitative information during design of the casting. For cast iron foundries, the use of casting process simulation has become an important instrument to predict the robustness and reliability of their processes, especially since the influence of alloying elements, melting practice and metallurgy need to be considered to quantify the special shrinkage and solidification behavior of cast iron. To be able to quantitatively predict these defects, solidification simulation had to be combined with density and mass transport calculations, in order to evaluate the impact of the solidification morphology on the feeding behavior as well as to consider alloy dependent feeding ranges. Therefore, it is not enough to base the prediction of shrinkage defects solely on hot spots derived from temperature fields.

#Magmasoft system requirements free#

Depending on the alloy poured, different feeding behaviors and self-feeding capabilities need to be considered to provide a defect free casting. The support of the feeding related layout of the casting is still one of the most important duties for casting process simulation. During the last 20 years, casting process simulation has developed from predicting hot spots and solidification to an integral assessment tool for foundries for the entire manufacturing route of castings. New products such as wind turbines have opened new markets for an entire suite of highly reliable ductile iron cast components. The mechanical engineering industry has recognized the value in substituting forged or welded structures with stiff and light-weight cast iron castings. Sturm and Guido Busch (MAGMA Gieereitechnologie GmbH, Aachen, Germany)Ībstract: High strength compacted graphite iron (CGI) or alloyed cast iron components are substituting previously used non-ferrous castings in automotive power train applications.

His work in casting metal research and casting process simulation has led to more than 150 publications and various contributions in scientific and technical books. Since 2005 he is head of sales & engineering.

From 1989 until today he has been working with MAGMA Gieereitechnologie GmbH, Aachen as a project manager and from 1990 on as head of international sales and marketing. In 1990 he received a Dr.-Engineer (Ph.D) degree. From 1984 until 1989 he worked as a research engineer at the Foundry Institute on the prediction of casting properties of aluminium alloys using simulation tools. He received his degree as a Diplom-Engineer of Foundry Technology at RWTH University Aachen in 1984.

0 kommentar(er)

0 kommentar(er)